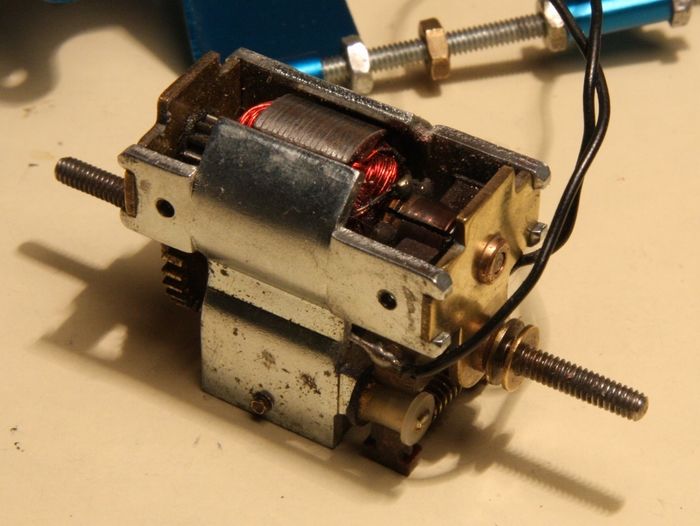

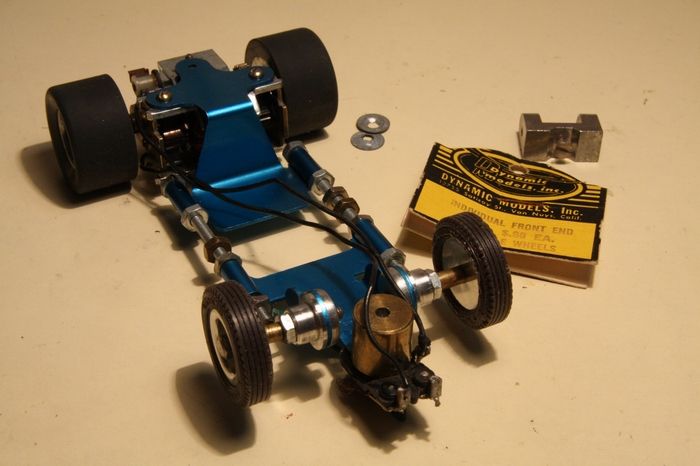

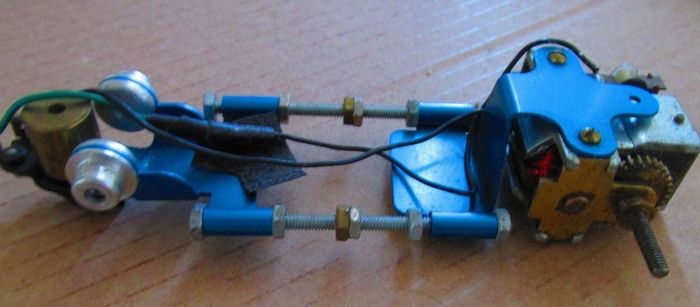

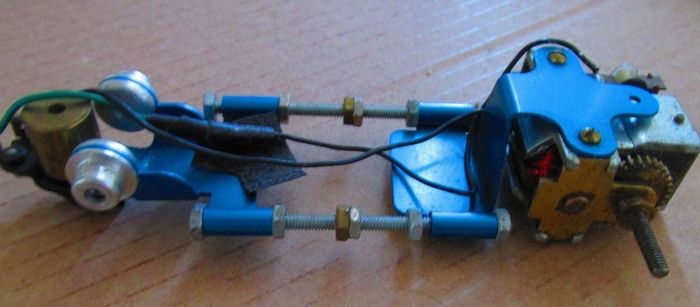

Hi everybody. I have recently bought this Garvic chassis

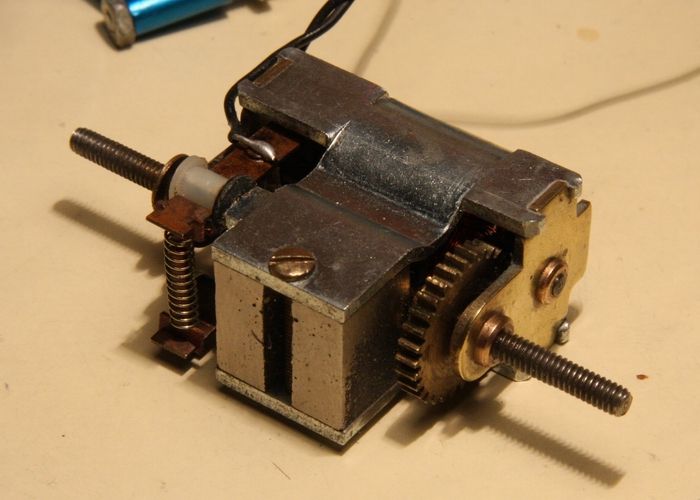

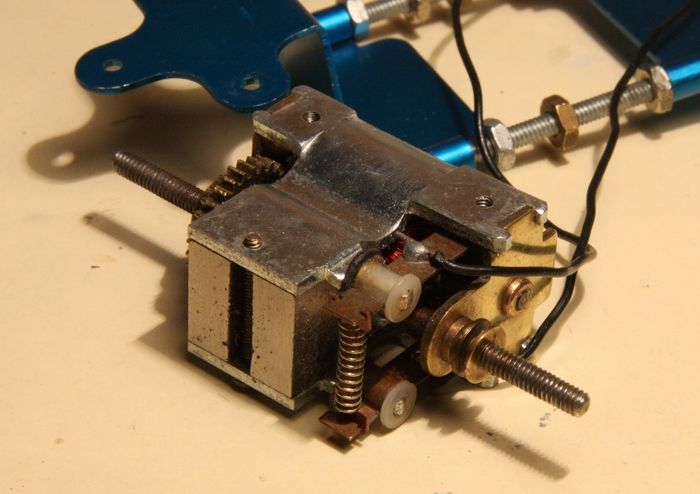

The aluminium pieces at the front are not oilites, but are 5-40 threaded. They seem to be original fitment. Does someone know if Garvic produced some kind of front axle (probably split) for this chassis, or may provide a copy of the original instruction sheet to see which was Garvic's recommendation about? There is a similar Garvic chassis for the Bonner motor that comes with ordinary oilites, but I can't imagine what was intended to be done with these threaded pieces. (Cutting an ordinary axle in two and installing free wheels retained by collars on the outside may be a solution, but it don't seems to me neat enough for being the factory recommendation)

Needless to say, any advice will be greatly appreciated. I would like to build up a car keeping as close as possible to what could have been done at the time, so any advice about suitable bodies will also be very welcomed.

Cheers,

Eduardo.

The aluminium pieces at the front are not oilites, but are 5-40 threaded. They seem to be original fitment. Does someone know if Garvic produced some kind of front axle (probably split) for this chassis, or may provide a copy of the original instruction sheet to see which was Garvic's recommendation about? There is a similar Garvic chassis for the Bonner motor that comes with ordinary oilites, but I can't imagine what was intended to be done with these threaded pieces. (Cutting an ordinary axle in two and installing free wheels retained by collars on the outside may be a solution, but it don't seems to me neat enough for being the factory recommendation)

Needless to say, any advice will be greatly appreciated. I would like to build up a car keeping as close as possible to what could have been done at the time, so any advice about suitable bodies will also be very welcomed.

Cheers,

Eduardo.